- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Handheld Laser Welding: The Difference Between Air Cooling and Water cooling, How to Choose The Right Equipment?

2025-01-08

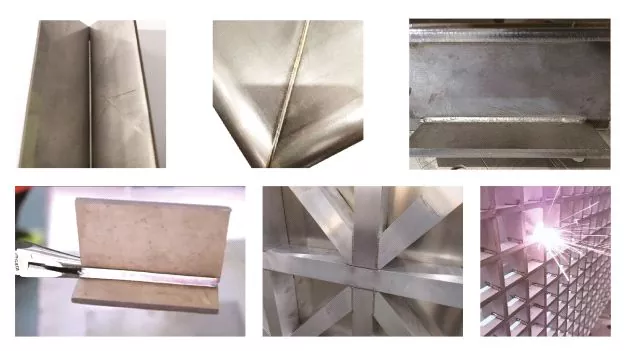

As an industry-leading laser equipment supplier, Huawei Laser has launched a number of high-performance handheld laser welding machines, including 800W-1500W air-cooling handheld laser welding machine, and 1500W-3000W water-cooling handheld laser welding machine. These products cover medium and low power to high power requirements, providing users with a variety of choices, and are widely used in multiple industries.

Operating environment: portability and applicability

Air-cooling handheld laser welding

Air-cooled equipment uses air as the cooling medium and does not require an additional water cooling system, so the overall structure is lighter and more compact, making it easier to carry and operate. This type of equipment is very suitable for small and medium-sized enterprises, light industrial production, and work scenarios that require frequent movement, such as outdoor construction or temporary welding tasks.

Water-cooling handheld laser welding

Water-cooled equipment relies on a built-in or external water circulation system for heat dissipation, and has a more complex structure, usually requiring a larger space to place the equipment and water tank. Therefore, water-cooled equipment is more suitable for fixed working environments, such as factory workshops and assembly line operations, especially in industrial scenarios that require high stability of the working environment.

Power : Adapt to different welding needs

Air-cooling handheld laser welding

The heat dissipation efficiency of air-cooled equipment is limited, so it is suitable for medium and low power laser welding tasks from 800W to 1500W, which can well meet the application scenarios with low power requirements such as thin metal plate processing, home appliance repair and advertising sign production.

Water-cooled handheld laser welding

The water-cooling system can support high-power laser welding tasks from 1500W to 3000W due to its efficient heat dissipation capacity. It is particularly suitable for the needs of thick plates and complex welding processes. It is an ideal choice for metal processing, automobile manufacturing and machinery manufacturing industries.

Heat dissipation performance: guarantee of continuous operation

Air-cooling handheld laser welding

Air-cooled equipment achieves heat dissipation through air flow. Although it is suitable for short-term, medium and low-intensity operations, it may have insufficient heat dissipation problems when used for a long time or with high power output.

Water-cooled handheld laser welding

Water-cooled equipment achieves efficient heat dissipation through water circulation, which can keep the temperature of the welding head stable for a long time, and is more reliable in high-intensity and long-term operations, avoiding equipment overheating that affects welding quality or shortens service life.

Post-maintenance: cost and operation complexity

Air-cooling handheld laser welding

Due to the lack of a water circulation system, the post-maintenance of air-cooled equipment is relatively simple. It only requires regular cleaning of the air filter device, and the maintenance cost is low. It is suitable for users with limited budgets or who pursue simple maintenance.

Water-cooling handheld laser welding

Water-cooled equipment requires regular inspection and replacement of coolant, cleaning of water tanks and water systems to prevent scale and blockage problems. Although maintenance is more complicated, it can significantly extend the life of the equipment and ensure its stability in high-power operations.

How to choose a suitable laser welding machine

When choosing equipment, users should comprehensively consider welding requirements, working environment, budget and long-term use costs. Air-cooled handheld laser welding is suitable for lightweight working environments and medium and low-power welding requirements, while water-cooled handheld laser welding is more suitable for high-intensity and long-term working scenarios.

For further information, please contact Huawei Laser, and we will provide you with professional laser welding solutions.