- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

The Difference and Advantages of Fiber Laser Cutting Machine and CNC

2025-01-07

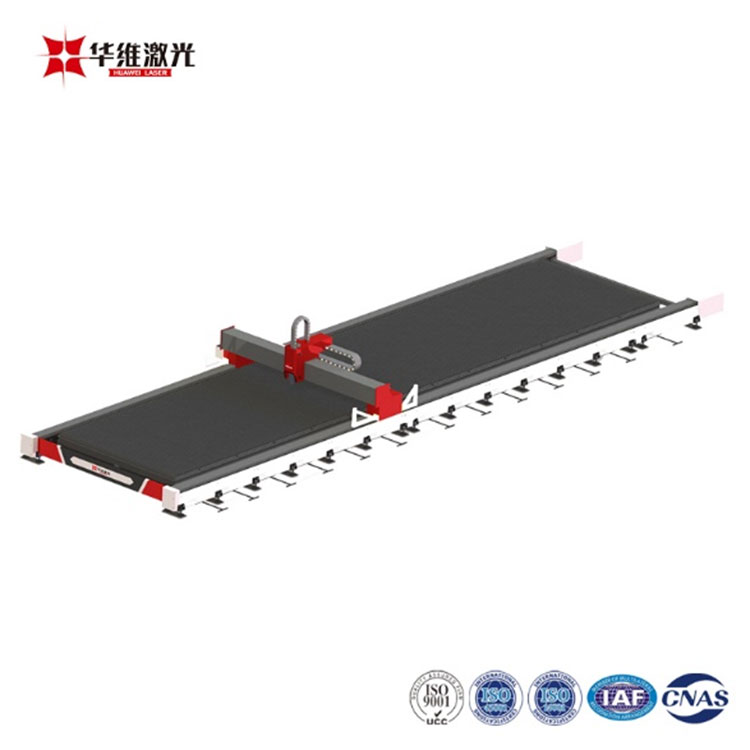

In recent years, with the continuous development of the manufacturing industry, fiber laser cutting machine and CNC have become the core equipment in the field of high-precision processing. Although both are powerful tools for industrial manufacturing, there are significant differences in technical principles, application scenarios and performance advantages. Compared with traditional CNC machine tools, fiber laser cutting machines have played a significant role in precision, efficiency and application flexibility.

Difference in technical principles

CNC mainly uses mechanical tools for cutting processing, which realizes part forming by milling, milling, turning and other operations on materials. This method is suitable for the processing of a variety of materials, including metals, However, CNC processing often requires the replacement of tools to adapt to different processing requirements, and efficiency may be limited in the processing of complex shapes.

The fiber laser cutting machine uses a high-power density laser beam to focus on the surface of the material, so that the material is quickly melted, vaporized or ablated, and the detector is blown away by auxiliary gas, thereby achieving precise cutting. The fiber laser cutting machine consumes physical contact and can complete the processing of complex-shaped workpieces in a short time.

Main advantages of fiber laser cutting machine

Efficient cooperation

Fiber laser cutting machine can achieve micron-level precision, and its laser beam diameter is extremely small, which is suitable for precision cutting of complex shapes. At the same time, when processing thin metal materials, its speed is several times faster than CNC, which greatly improves production efficiency.

Wide material applicability

Fiber laser cutting machine is suitable for a variety of metal materials, including stainless steel, carbon steel, aluminum alloy and copper, etc., and is not limited by mechanics and reflectivity, which has obvious advantages in industrial manufacturing.

Low operating cost

No focus fatigue problem, keeping cost low. At the same time, its laser has low power consumption, energy saving and environmental protection, which significantly reduces operating costs for enterprises.

Automation and customization

Laser cutting equipment can realize fast processing by importing design drawings through software, and the intelligent typesetting function effectively improves material utilization and global production preparation time.

As a leading company in fiber laser cutting technology, Huawei Laser provides high-performance and high-precision cutting equipment to global customers through continuous innovation. Its products are widely used in automobile manufacturing, aerospace, metal processing and home appliance manufacturing, helping enterprises to reduce costs and increase efficiency and promote industrial upgrading. In the future, Huawei Laser will continue to lead the industry's technological transformation and help the manufacturing industry reach new heights of intelligence and high-quality development!