- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Choose the Suitable Model for Industrial Robots

2025-01-14

In the field of automation, it may be easy for senior mechatronics engineers to choose the right "robot". However, for designers or factories who are preparing to purchase and import robots for the first time, this process may become a bit confusing and challenging.

Don't worry, Huawei Laser, as a leading industrial automation solution provider in the industry, will analyze in detail how to accurately choose an industrial robot that meets your needs from the following professional parameter dimensions. With many years of professional experience in the industry, Huawei Laser will provide you with all-round support and professional guidance to ensure that you make the most appropriate choice.

Clear application scenarios

Different production links and work tasks have very different requirements for industrial robots. For example, in the welding process of automobile manufacturing, high-precision and high-stability welding robots, such as welding positioners, welding robot workstations, etc., are required to ensure welding quality and uniformity of welds. If it is the assembly of electronic components, the flexibility and precision of the robot are required to be high, and collaborative robots or assembly robots with multiple end effectors and interfaces are more suitable.

Consider key parameters

• Payload: The maximum load that a robot can carry in its workspace is an important basis for selection. It is necessary to comprehensively consider the weight of the workpiece and the weight of the robot gripper, and pay attention to the load curve. The actual load capacity may be different in different spatial positions.

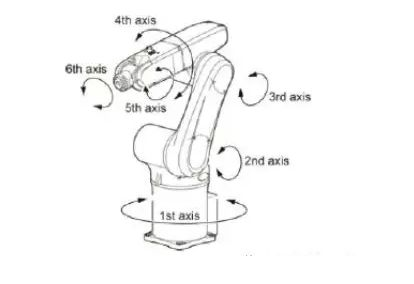

• Degrees of freedom (number of axes): The number of axes determines the flexibility of the robot. For simple pick-and-place tasks, a 4-axis robot may be sufficient; in complex scenarios where the arm needs to twist and turn more in a small space, a 6-axis or 7-axis robot is a better choice.

• Repeat accuracy: This indicator depends on the application, and the range is generally between ±0.05mm and ±0.02mm or even more precise. For precision operations such as electronic circuit board assembly, ultra-high-precision robots are required; while for rougher processes such as packaging and palletizing, the accuracy requirements are relatively low.

• Speed: Depends on the Cycle Time of the operation. The maximum speed in the specification table needs to be considered in combination with the actual acceleration and deceleration conditions, and the unit is usually in degrees/second.

• Protection level: Select a robot with the corresponding protection level according to the use environment. If working in special environments such as food, medicine, flammable and explosive environments, you need to choose a model that meets the corresponding standards, such as IP67.

Other factors

• Repairability and maintenance cost: Choosing a robot model that is easy to repair and has low maintenance costs can reduce the company's operating costs.

• Safety: When working, the robot may collaborate with humans or approach human work areas. It is necessary to ensure that it has safety certification and complete protection measures.

• Scalability and upgradeability: As production needs change, the functions and performance of robots need to be continuously upgraded. Models with good scalability and upgradeability are more adaptable to future development.

Choose the right robot to achieve efficient production!

Whether it is the first time to introduce automation equipment or optimize and upgrade existing production lines, choosing the right robot is the first step towards success. With a professional technical team and comprehensive solutions, Huawei Laser will work with you to customize the most suitable automation layout and take productivity to a new level.

For further information, please feel free to contact us!