- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

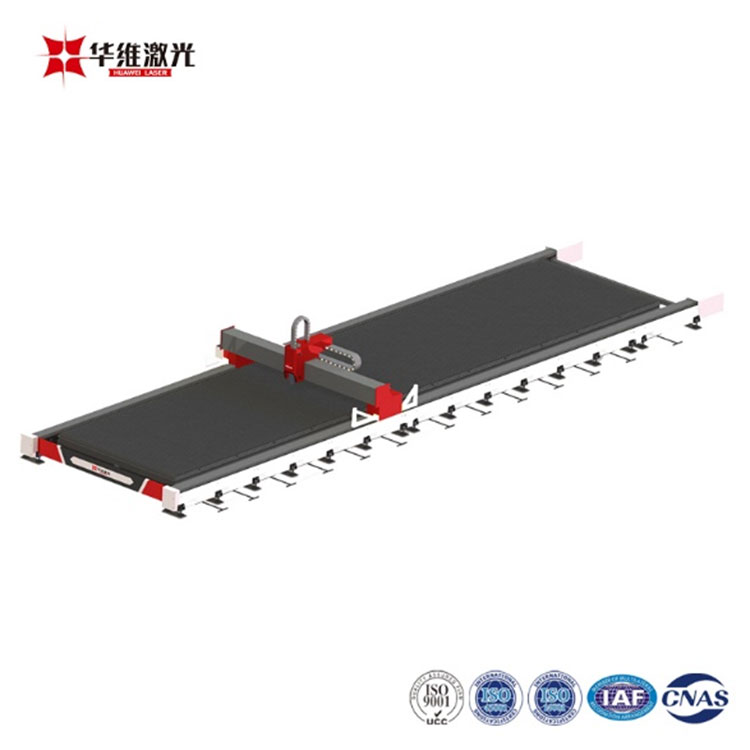

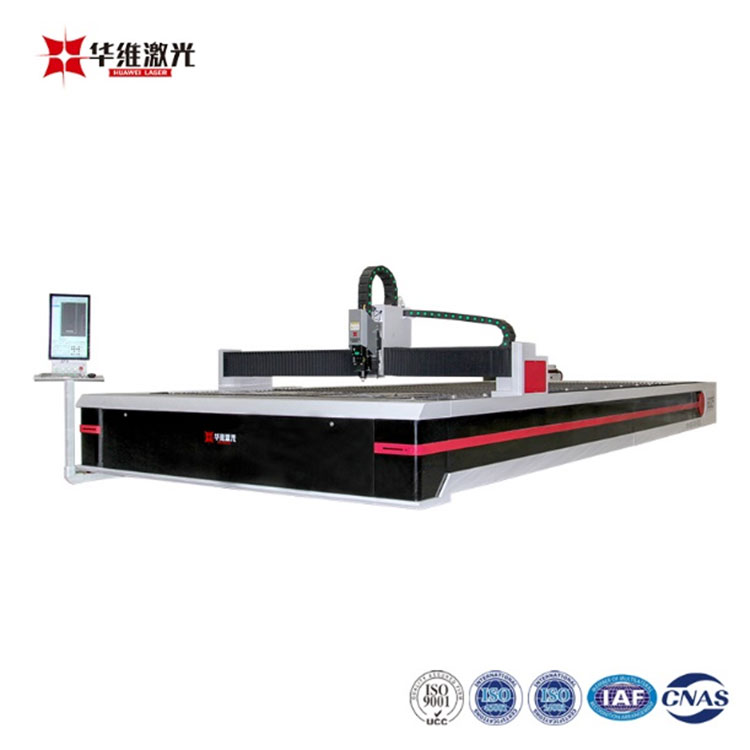

12000W Sheet Tube Laser Cutting Machine

As a professional fiber laser cutting machine manufacturer, manufacturer and supplier in China, Shenyang Huawei Laser specializes in the production of: open laser cutting machines, ultra-large format 10,000-watt laser cutting machines, tube-sheet integrated laser cutting machines, pipe laser cutting machines , handheld laser welding machine. Welcome to buy 12000W Sheet Tube Laser Cutting Machine from us. It can perform precision processing on carbon steel, stainless steel, copper, aluminum, aluminum alloy and other materials.

Send Inquiry PDF DownLoad

Huawei Laser was established in 2017. As a professional manufacturer of 10,000-watt laser cutting machines in China and the factory of 10,000-watt laser cutting machines in China, we have strong strength and perfect management. At the same time, we have our own export qualifications. We mainly produce open laser cutting machines, ultra-large-format 10,000-watt laser cutting machines, Sheet tube integrated laser cutting machine, pipe laser cutting machines, industrial laser cleaning equipment, handheld laser welders, etc. We adhere to the principle of quality first and customer first, and sincerely welcome your letters, calls, inspections and business negotiations. We always guarantee you high quality service.

Model specification identification method

|

HWST-12000W-13031-220 |

|

HW:HuaWei Laser |

|

ST: Sheet Tube |

|

12000W:Power |

|

13031:Cutting range(X Axis:3100mm、Y Axis:13000mm) 220:Diameter≤220mm Side Length≤220*220mm |

Product Features Of 12000W Tube Sheet Laser Cutting Machine

Functional Complementarity;Higher Efficiency;Convenient Maintenance;

Double-drive gantry structure, which combines the excellent thermal treatment technology with machining technology to ensure machine rigidity and long-term stable use;

The integrated design of sheet cutting and tube cutting can switch sheet and tube flexibly according the production requirements, which can meet the customers' demand on cutting process to the greatest extent;

The cutting function can achieve 6m and 3m pipe cutting.

Cutting Samples Of 12000W Sheet Tube Integrated Laser Cutting Machine:

Application of Of 12000W Sheet Tube Laser Cutting Machine:

Suitable for stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel titanium alloy, Inconel alloy, titanium alloy and other metal materials. It is widely used in various manufacturing industries such as aerospace, automobiles and ships, machinery manufacturing, elevator manufacturing, advertising production, household appliance manufacturing, medical equipment, hardware, decoration, and metal external processing services.

Technical Parameters of 12000W Sheet Tube Laser Cutting Machine

|

Power |

12000W |

|||

|

Model(HWST) |

4020 |

6025 |

13031 |

|

|

Plate cutting range |

4m*2.0m |

6m*2.5m |

13m*3.1m |

|

|

Tube cutting range |

Round tube diameter≤220mm Rectangular tube≤220*220mm |

|||

|

Position accuracy |

±0.02mm |

|||

|

Cutting thickness (reference data) |

Carbon steel |

35mm |

||

|

Stainless steel |

25mm |

|||

|

Supply voltage |

AC380V ±10% 50Hz |

|||

|

Remark |

Other workbench sizes can be customized according to customer requirements |

|||

Main component parts 12000W Tube Sheet Laser Cutting Machine:

1.BOCHU SYSTEM

The FSCUT system is a very popular operating system for professional laser cutting machines. It is easy to install and debug, has excellent performance and provides a complete solution.

The system has functions such as automatic edge finding, common edge cutting, perforation and slag removal, compensation function, thin plate flying cutting, fault self-detection, automatic conversion of CAD drawings, and automatic memory.

2.laser generator

Modular design, stable performance; easy maintenance, high reliability; customizable to meet various needs; uniform spot energy distribution, stable processing; multiple scenarios, wide application.

3.Laser cutting head

Functional features: nine-level perforation, intelligent knife closing, traceless micro-connection, automatic return cutting, melt pool detection, intelligent perforation.

High cost performance: the first choice for economical laser cutting equipment;

Excellent design: optimized optical configuration and smooth and efficient air flow design significantly improve cutting quality and efficiency;

Exquisite structure: extremely light weight and compact size, which reduces the load requirements of the robot and improves the cutting speed and quality.

4.The bed is welded with a steel structure, and is precision machined after overall annealing to improve stability and feature high strength and adaptability.

5.The cross beam adopts extrusion and stretching manufacturing process to reduce weight, improve rigidity and greatly improve the response speed of the machine tool.

FAQ Of 12000W Sheet Tube Integrated Laser Cutting Machine:

1、Q: I don’t know which one is suitable for me ?

A :Just tell us below information

1) Max work size:choose most suitable model.

2) Materials and Cutting thickness:To match the right Power of laser generator for you.

3) Business industries:We sell a lot and give advice on this business line.

2.Q: When I got this machine, but I don’t know how to use it. What should I do?

A:We will send training video and English manual with the machine in time. If you still have some doubts, we can talk by telephone or skype and

e-mail.

3、Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

4、Q: How can I do if the machine goes wrong?

A: If confronted with such problems, Non-professionals should not repair the machine,please contact us ASAP. We will response within 24 hours as quick as we can to solve it for you.